Home page / Catalogue / Products of «BRP» / Molded goods / Refractory products for lining of steel teeming ladles

Refractory products for lining of steel teeming ladles

Refractory products for lining of steel teeming ladles

Refractory products for lining of steel teeming ladles are designed for lining of steel teeming ladles and other thermal units

Technical characteristics

|

|

Norm for mark |

||||

|---|---|---|---|---|---|

|

|

SHKU-32 |

SHKU-37 |

MKRKU-45 |

MKRKP-45 |

MLKS-62 |

|

GOST 5341-2016 |

|||||

|

Mass fraction, %: Al2O3, no less Al2O3, over Fe2O3, no more |

32 - - |

37 - - |

- 45 3,5 |

- 45 3,5 |

- 62 1,4 |

|

Refractory property, °C, no low than |

1690 |

1730(1710)* |

1730 |

1730 |

- |

|

Compressive resistance, N/mm2, no less |

27 |

30(27)* |

35 |

40 |

30 |

|

Open porosity, %, no more |

19 |

18(19)* |

18 |

16 |

22 |

|

Residual changes in the sizes during heating,%, no more, at the temperature:

|

+0,3 |

+0,3 |

+0,4 |

+0,2 |

- |

|

Onset temperature of softening, °C, no low than |

1370 |

1400(1370)* |

1400 |

1400 |

1450 |

|

Thermal resistance, thermal cycling , no less |

4 |

4(3)* |

3 |

4 |

- |

* The indicator values for products made from the clays of the Arkalyk and Berlin natural occurrence are indicated in brackets

Technical characteristics

|

|

Norm for mark |

||||

|---|---|---|---|---|---|

|

|

MLKU-62 |

MLKU -69 |

MKKS-72 |

MKKS-75 |

MKKS-90 |

|

GOST 5341-2016 |

|||||

|

Mass fraction, %: Al2O3, no less Al2O3, over Fe2O3, no more |

- 62 1,1 |

69 - 1,0 |

- 72 1,5 |

75 - 2,2 |

90 - 0,8 |

|

Compressive resistance, N/mm2, no less |

50 |

50 |

30 |

40 |

50 |

|

Open porosity, %, no more |

17 |

19 |

24 |

23 |

24 |

|

Residual changes in the sizes during heating, %, no more, at the temperature:

|

- |

- |

+1,0 |

+2,5 |

- |

|

Onset temperature of softening, °C, no low |

1600 |

1650 |

1500 |

1420 |

1660 |

|

Thermal resistance*, thermal cycling , no less |

15 |

15 |

- |

3 |

- |

* It is determined by the agreement of the consumer with the producer.

|

|

Norm for mark |

||

|---|---|---|---|

|

|

KMKRU -45 |

KMKRU -50 |

KMKRU -55 |

|

ТS 14-8-647-94 with a change1-3 |

|||

|

Mass fraction, %: Al2O3, no less Fe2O3, no more |

45 3,5 |

50 4,4 |

55 4,0 |

|

Refractory property, °C, no low |

1730 |

1730 |

1730 |

|

Compressive resistance, N/mm2, no less |

35 |

33 |

35 |

|

Open porosity, %, no more |

19 |

19 |

19 |

|

Residual changes in the sizes during heating, %, no more, at the temperature: 1400 °C |

0,4 |

0,4 |

0,4 |

|

Thermal resistance, thermal cycling , no less than |

4 |

4 |

4 |

|

|

Norm for mark |

|

|---|---|---|

|

|

KBU |

KBU |

|

ТS 14-194-300-10 with a change 1 |

||

|

Mass fraction, %: Al2O3, no less Fe2O3, no more |

55 4 |

60 3 |

|

Refractory property, °C, no low |

1750 |

1770 |

|

Compressive resistance, N/mm2, no less |

35 |

45 |

|

Open porosity, %, no more |

20 |

19 |

|

Residual changes in the sizes during heating, %, no more than, at the temperature: 1400 °C |

up -0,4 to +1,0 |

up -0,4 to +1,0 |

|

Thermal resistance, thermal cycling , no less |

4 |

6 |

Form and sizes

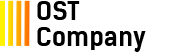

Double sided neck brick

|

Product number |

Sizes, mm |

Complexity unit |

|||

|---|---|---|---|---|---|

|

|

S |

S1 |

L |

H- thickness of course |

|

|

1 |

140 |

120 |

250 |

65 |

3 |

|

2 |

140 |

125 |

250 |

80 |

4 |

|

2а |

80 |

68 |

300 |

120 |

4 |

|

2b |

80 |

68 |

300 |

160 |

4 |

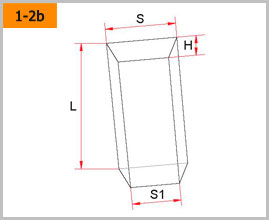

Double sided trapezoidal brick

|

Product number |

Sizes, mm |

mComplexity unit |

|||

|---|---|---|---|---|---|

|

|

S |

S1 |

L |

H- thickness of course |

|

|

3 |

140 |

135 |

250 |

65 |

3 |

|

4 |

140 |

135 |

250 |

80 |

4 |

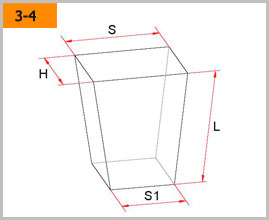

Double sided trapezoidal brick

|

Product number |

Sizes, mm |

Complexity unit |

|||

|---|---|---|---|---|---|

|

|

S |

S1 |

L |

H- thickness of course |

|

|

6 |

250 |

239 |

80 |

80 |

4 |

|

7 |

210 |

181 |

100 |

80 |

4 |

|

8 |

230 |

209 |

100 |

80 |

4 |

|

9 |

250 |

236 |

100 |

80 |

4 |

|

10 |

210 |

176 |

120 |

80 |

4 |

|

11 |

230 |

206 |

120 |

80 |

4 |

|

12 |

230 |

212 |

120 |

80 |

4 |

|

13 |

250 |

235 |

120 |

80 |

4 |

|

14 |

210 |

178 |

150 |

80 |

4 |

|

14а |

225 |

205 |

150 |

80 |

4 |

|

15 |

230 |

205 |

150 |

80 |

4 |

|

15а |

245 |

210 |

150 |

80 |

4 |

|

16 |

250 |

232 |

150 |

80 |

4 |

|

16а |

250 |

228 |

150 |

80 |

4 |

|

18 |

220 |

192 |

200 |

80 |

4 |

|

19 |

240 |

216 |

200 |

80 |

4 |

|

20 |

230 |

200 |

250 |

80 |

4 |

|

21 |

250 |

221 |

250 |

80 |

4 |

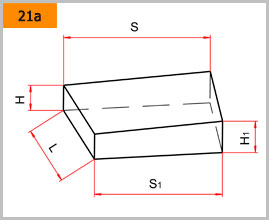

Wedge product

|

Product number |

Sizes, mm |

Complexity unit |

||||

|---|---|---|---|---|---|---|

|

|

S |

S1 |

L |

H1 |

H- thickness of course |

|

|

by proportion b/b1≥1/ |

||||||

|

21a |

240 |

213 |

200 |

60 |

80 |

4 |

|

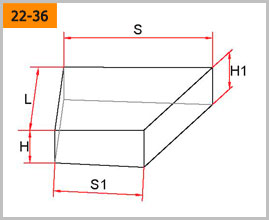

Product number |

Sizes, mm |

Complexity unit |

||||

|---|---|---|---|---|---|---|

|

|

S |

S1 |

H |

H1 |

L- thickness of course |

|

|

by proportion b/b1≤1 |

||||||

|

22 |

230 |

205 |

40 |

40 |

150 |

4 |

|

23 |

230 |

205 |

40 |

50 |

150 |

4 |

|

24 |

230 |

205 |

50 |

60 |

150 |

3 |

|

25 |

230 |

205 |

60 |

70 |

150 |

4 |

|

26 |

230 |

205 |

70 |

80 |

150 |

4 |

|

27 |

220 |

192 |

40 |

40 |

200 |

4 |

|

28 |

220 |

192 |

40 |

50 |

200 |

4 |

|

29 |

220 |

192 |

50 |

60 |

200 |

3 |

|

30 |

220 |

192 |

60 |

70 |

200 |

4 |

|

31 |

220 |

192 |

70 |

80 |

200 |

5 |

|

32 |

250 |

221 |

40 |

40 |

250 |

5 |

|

33 |

250 |

221 |

40 |

50 |

250 |

4 |

|

34 |

250 |

221 |

50 |

60 |

250 |

4 |

|

35 |

250 |

221 |

60 |

70 |

250 |

4 |

|

36 |

250 |

221 |

70 |

80 |

250 |

5 |

Straight brick